silicone gasket,polythene gasket,silicone washer,rubber washer/seal washer,seal gasket,cushion ring,gasket,flat ring,nylon gasket

Size:IDM2/2.5/3/4/5/6/8/10/12/14/16/18/20

Material:Nylon,plastic,silicone ,rubber.

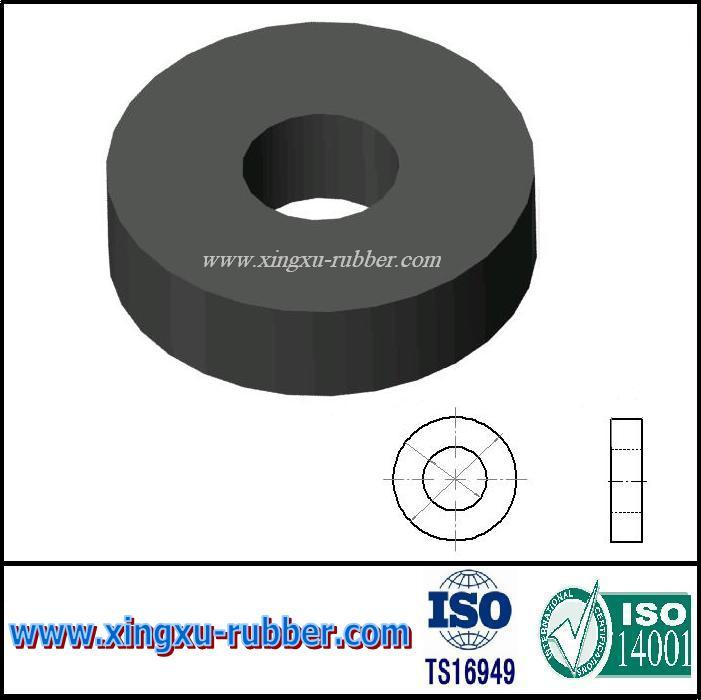

Rubber gasket

Rubber gasket has oil resistance, acid and alkali resistant, cold and heat, resistance and aging resistance, directly cut into various shapes of sealing gasket, which is widely used in medicine, electronics, chemical, antistatic, flame retardant, food and other industries.

Related products and Applications

Rubber gasket gasket rubber in the metal flange or other connecting parts between the two static surface of the sealing effect of the thin sheet of rubber products, rubber gasket. Can be made by molding method, also can be used for curing the film. Can be widely used in a variety of mechanical equipment, from the pad, seal, buffer, etc.. [1]

From the form, commonly used rubber washer washer include: rubber flat washers, rubber O-ring, plastic flat gasket, PTFE gasket package, asbestos rubber gasket, metal flat washers, metal washers special-shaped, metal foreskin washers, wave washers, washers and other entangled.

(1) rubber flat washers: easy deformation, pressure, but not hard, but the pressure, temperature resistance is poor, only for low pressure, low temperature. Natural rubber have a certain resistance and alkali resistance, using the temperature should not exceed 60 DEG C; chloroprene rubber and ability of acid-base, use temperature is 80 DEG C; nitrile rubber oil resistant, available to 80 DEG C; fluorine rubber resistance corrosion resistance good, high temperature performance than general rubber strong, used in 150 DEG C medium.

(2) rubber gasket: cross sectional shape is a circle, the role of certain self tight, seal better than flat washers, and pressed a smaller force.

From the material, the main products include: silicone rubber pad pad, nitrile rubber pad, rubber pad, rubber pad and other fluorine. Rubber gasket has oil resistance, acid and alkali resistant, cold and heat, resistance and aging resistance, directly cut into various shapes of sealing gasket, which is widely used in medicine, electronics, chemical, antistatic, flame retardant, food and other industries.

silicon rubber

Has outstanding resistance to high and low temperature performance, in the temperature range of - 70 degrees to 260 DEG C to keep good elasticity, ozone resistance, weather aging resistance, suitable for thermo mechanical seal gasket. Non-toxic and can be made of heat insulation, insulation products and medical rubber products. At the same time with waterproof, flame retardant, high temperature resistance, conductive, wear-resistant, oil and other excellent performance, widely used in machinery, electronics, plumbing and other industries.

Nitrile rubber

NBR (Rubber Nitrile-Butadiene) is a polymer formed by emulsion copolymerization of butadiene and acrylonitrile, which is known for its excellent oil resistance, and also has good wear resistance, aging resistance and air tightness. So it is widely used in rubber industry.

Fluorine rubber

With high temperature resistance, can be used in the +200 C -20 C environment, the strong oxidizing agent, oil, acid and alkali resistance. Usually used in high temperature, high vacuum and high pressure environment, it is also suitable for oil environment, widely used in petroleum, chemical, aviation, aerospace and other departments.

Other

Chloroprene rubber, natural rubber, EPDM [2] three gum, acrylic glue and other special rubber. With oil, acid, alkali, wear-resistant, high and low temperature properties.

main parameter

Product name using temperature using pressure commonly used specifications

Nitrile rubber gasket -20 ~110 DEG C PN<=16MPa DN15 ~ DN400

Fluorine rubber gasket -20 C ~200 C PN<=16MPa C DN15 ~ DN400

Natural rubber gasket -50 C ~80 C PN<=16MPa C DN15 ~ DN400

Chloride butyl rubber gasket -20 C ~100 C PN<=16MPa C DN15 ~ DN400

Three EPDM gasket -57 C ~176 <2.5MPa DN15 ~ DN400 pressure

Silicone rubber gasket -100 C ~300 C pressure DN15 <3.0MPa ~ DN400

Standard for use of rubber gaskets

Give full play to the characteristics of various gaskets, in the use of rubber gaskets, should fully consider the following factors:

Have a good flexibility and resilience, can adapt to changes in pressure and temperature fluctuations have the appropriate flexibility, can be a good fit with the contact surface;

Non polluting process medium;

Low temperature does not harden, small shrinkage;

Good processing performance, easy to install and press;

Non adhesive sealing surface, easy disassembly.

Application of rubber gasket

Rubber gaskets are widely used in automotive, electronic, chemical, antistatic, flame retardant, food, all kinds of mechanical equipment and other industries, can play the role of gasket, seal, buffer, etc..

Method for making rubber gasket

In 1500mm within the scope of any size cutting rubber gasket are molded, cutting, molding is using hydraulic molding machine and mold pressing and, cutting the cutting machine cutting out with a gasket, compared with molding material saving, but relatively simple, a pair of mold can only do a gasket, gasket cutting machine to cut the can, but on board the rate is not very high.